Faryan Industrial Automation Design Company is ready to provide industrial automation services in the fields of electrical and instrumentation engineering as well as electronic systems for the implementation of industrial automation projects.

The company’s areas of activity cover the design of industrial automation systems for a wide range of industries, including oil, gas, and petrochemical industries, as well as the food industry (such as food production and packaging lines, filling machines, labeling machines, plastic injection systems, tower cranes, and more).

The geographical scope of Faryan Industrial Automation’s operations is not limited to Tehran, Karaj, or other provinces of Iran—it extends throughout the Middle East. The company has successfully completed various projects in countries such as Kuwait, the United Arab Emirates, Iraq, Turkey, Afghanistan, and Uzbekistan.

Industrial Automation Services

The Faryan Industrial Group provides the following industrial automation services:

Design and implementation of industrial automation systems

Installation and commissioning of electrical and instrumentation systems

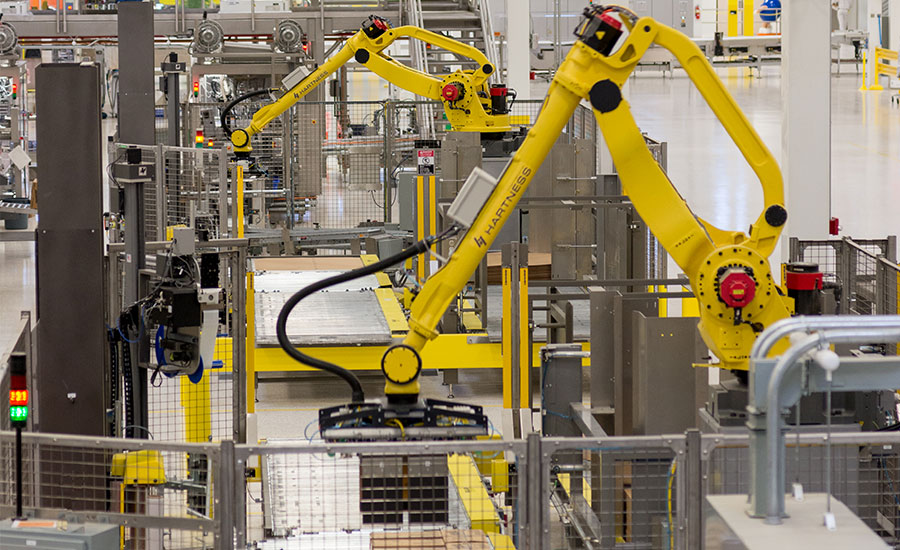

Upgrading and overhauling of used machinery

Modernization and upgrading of factory production lines

Preparation of material take-off (MTO) lists for electrical, instrumentation, and control systems, as well as detailed engineering of projects

Supply of equipment and industrial components with procurement engineering services

Design of Distributed Control Systems (DCS)

Troubleshooting and repair of industrial automation systems

Execution of industrial automation projects

Equipment supply for factories

Design and preparation of P&ID (Piping and Instrumentation Diagram) reports

Implementation of industrial automation projects

Design and construction of electrical panels with wiring

Programming of Programmable Logic Controllers (PLCs)

Design and manufacturing of electronic boards

PC-based control system programming

Microcontroller system programming

Providing control and automation systems using Servo Drive & Servo Motor equipment

Basic Engineering services

Detailed Engineering services

Preparation of Logic Diagrams, finalization of line equipment specifications, finalization of I/O system specifications, and finalization of required control system specifications

Industrial Automation Design

The Control Systems Department is responsible for all specialized activities in the fields of process control and safety systems. With the support of professional project managers, experienced technical experts, and by utilizing the latest technical knowledge, this department performs the design, engineering, manufacturing, and factory acceptance testing (FAT) of process and safety systems.

This is accomplished through the integration of DCS, FCS, ESD, FGS, BMS, as well as PLC process packages and MMS in various projects. These systems are implemented in EPC projects, oil and gas transmission pipelines, petrochemical complexes, refineries, utility units, water treatment plants, mining, and the steel industry.

Our services in this section include:

Providing engineering services for control and safety systems based on relevant international standards.

Supplying control and safety system components from reputable and approved vendors according to the customer’s AVL (Approved Vendor List), as well as manufacturing, configuration, and FAT of these systems by Faryan Company across Iran.

Providing complete installation, pre-commissioning, and commissioning services for control systems.

Delivering professional training on control and safety systems at Faryan’s Training Center or at the customer’s site.

After receiving the client’s request and signing the contract, the following services are provided:

Basic Engineering Design

Estimation of required equipment considering automatic or semi-automatic operations

Detailed design and development of control system architecture

Preparation and design of project documentation

Design of required electrical panels

Panel design considering estimated equipment, layout, and assembly details

Preparation of engineering documents and technical specifications (Document List, Data Sheets)

Preparation of Logic Diagrams, I/O Lists

Preparation of SAT/FAT documents, FDS, Loop Diagrams, Network Configuration, Modbus Lists, and more

Design of control and power wiring diagrams using EPLAN and AutoCAD

PLC–HMI programming for control systems

Design of graphical user interfaces (HMI screens) for monitoring and control

Design and programming of PC-based monitoring systems using Visual Studio

Determining network protocols and data transmission methods

Providing telemetry systems for data acquisition and transmission

Supplying communication modules for control and monitoring of industrial equipment and machinery using PC & IPC

Panel assembly and functional testing before on-site installation

Installation, commissioning, and performance testing on process systems

Providing support, maintenance, and repair services depending on the project type and process sensitivity.